Read the Papers brings you fast access to the UK Daily Newspapers

01.01.2024

A picture says more than 1000 words....

» drucken « zurück

Large Number of Visitors at the Muller Martini Open House in China

01.01.2024

Visitors to the Open House, which Muller Martini organized together with its customer Shandong Xinhua Printing at the Jinan site

„We had actually planned a small-scale open house,“ explains Sven Olsen, Regional Director Muller Martini Asia Pacific. „But to our great delight, the announcement triggered a veritable rush of visitors.“ In the end, Muller Martini and the Shandong Xinhua Printing welcomed more than 120 visitors to the joint open house at the Jinan site. One of their two new Muller Martini Publica PRO 15 perfect binders was presented live by Shandong Xinhua

Printing.

The highly automated Publica PRO 15 line includes stream feeders, several end-of-line packaging alternatives, a Pluton palletizer from Solema and is equipped with the Connex workflow system. During the demonstration, the line was running at a speed of 14,000 copies/hour and was manned by just five people. „The demonstration was a real eye-opener for the customers present, who consisted of over 40 of China‘s largest government printing companies, including their top management,“ says Sven Olsen, emphasizing the enthusiasm of the visitors.

During the subsequent presentation, the extremely detailed equipment selection process and high requirements of Shandong Xinhua were emphasized. The reasons for investing in the Publica PRO 15 were not only the high production speed, the first-class quality of the end products and the high level of efficiency, but also the reduced need for manpower. This is because the Publica PRO 15 is operated at Shandong Xinhua Printing with 50 percent fewer personnel than previous models. As a result, Shandong Xinhua Printing - which operates three factories in Shandong Province (Jinan, Dezhou and Tai‘an) and, in addition to the two Publica PRO 15s, also have two Diamant/Collibri hardcover lines, a Ventura Connect system, a Bolero perfect binder and a number of older Muller Martini systems - has positioned themself at the forefront of printing factories in China.

» drucken « zurück

Unveiling Strategic Drivers Behind Our Presence at drupa 2024.

01.01.2024

PreMedia:

What upcoming developments or innovations do you anticipate in the printing industry at drupa 2024, Dr. Monz?

Dr. Ludwin Monz:

Our customers face three main challenges: ever-increasing cost pressure, a shortage of skilled workers and rising sustainability requirements. HEIDELBERG will be presenting solutions to these challenges at this year‘s drupa. Let me give you a brief overview.

Enormous competitive pressure is forcing our customers to reduce their costs. We will be presenting several innovations that increase productivity and reduce the cost per printed sheet in high-volume printing.

We are addressing the shortage of labour and skilled workers by further automating and digitalizing the print shop value chain. We will be presenting the further developed „push-to-stop“ technology and our Prinect workflow software solution.

And finally, we help our customers to improve the sustainability of their businesses and their products. We present technologies that help to save energy and reduce the consumption of raw materials.

In summary, HEIDELBERG is committed to maintaining its technology leadership in the printing sector by addressing the major challenges of modern printing.

PreMedia:

How do you perceive the future development of industries regarding sustainability and digitalization?

Dr. Ludwin Monz:

Sustainability in print production is one of the biggest trends worldwide and at the same time a major challenge for our industry. In modern print shops, the aim is to reduce the energy and resource consumption in order to become even more sustainable. But printed products are also changing, moving away from plastic and towards more paper.

But HEIDELBERG also has its own corporate goals when it comes to sustainability. Our goal is to achieve the smallest ecological footprint across the entire value chain in the printing industry.

HEIDELBERG has been an industry pioneer in the digitalization of printing for 20 years. Our main goal is to optimize our customers‘ entire value chain. To this end, we have fully digitalized and integrated the processes and thus offer our customers maximum efficiency in industrial print production, which ultimately leads to higher productivity and a reduction in costs. In the area of digitalization, HEIDELBERG offers stand-alone end-to-end solutions for both commercial and packaging customers.

So put HEIDELBERG on your list if you are looking for highly digitalized intelligent workflows at drupa.

PreMedia:

Can you share how you‘ve incorporated sustainability or digitalization into your company and the reasons behind those implementations?

Dr. Ludwin Monz:

HEIDELBERG offers sustainable printing solutions. We support our customers in saving energy and raw materials. If you compare a Speedmaster from 1990 with today‘s version, energy consumption per 1000 sheet has been reduced by up to 40 percent. At this year‘s drupa, we will be presenting the latestgeneration of presses with a maximum speed of up to 21,000 sheets per hour. This increase in production speed will help our customers to further reduce the energy consumption per sheet.

But speed alone is not enough. We have to take a holistic view of the machines. A good example of this is our Boardmaster flexographic printing machine. Thanks to the flying job change, the system works with very little waste. The water-based inks also improve the environmental balance. So from a product perspective, sustainability goes hand in hand: Energy efficiency, intelligent automation and environmentally conscious consumables.

With regard to digitalization, we are investing heavily in software solutions for integrated print production. Lean processes in the print shop and a highly automated control system help to make production more efficient. One example is our new HEIDELBERG customer portal. The digital all-in-one portal offers easy access to production and workflow apps, analytics, service and maintenance, material purchasing and administration tools. In the future, users will also benefit from other apps that automate the production workflow - for both digital and offset printing.

PreMedia:

What significance does drupa 2024 have for you as a presence trade fair?

Dr. Ludwin Monz:

In three words: Innovation, inspiration, networking.

» drucken « zurück

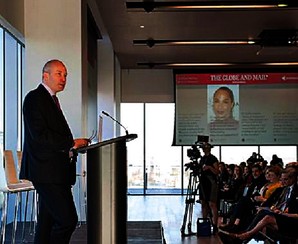

Gannett prints fake newspapers at Des Moines Register plant

15.12.2022

Every single product is perfect and ready for immediate sale: In print finishing, Muller Martini supports sustainable production

Fake newspapers designed to drive Illinois voters away from Democratic candidates are being printed at the Des Moines Register‘s plant, Gannett staff confirmed to Bleeding Heartland.

At least eleven printed publications, which are part of the conservative network Local Government Information Services (LGIS), have been distributed to Illinois residents since August. Sometimes known as „pink slime“ journalism, such publications combine political advocacy with stories resembling neutral coverage of local news or sports. The material has the look and feel of a newspaper, but the content is more like political advertising.

Jem Bartholomew of the Columbia Journalism Review was first to report in early October that Gannett had taken over printing of the LGIS products. The previous publisher, which also owns the suburban Chicago newspaper Daily Herald, canceled its commercial printing contract with LGIS in late September, saying „Many critics cannot or refuse to differentiate between a commercial printing operation“ and the Herald‘s „editorial mission to be unbiased and fair.“

The Des Moines Register‘s executive editor, Carol Hunter, had no comment beyond confirming in a November 4 email that „these are commercial print clients.“ She provided a statement from Gannett‘s corporate communications staff: „We do not discuss our commercial print clients and have no further comment.“

The Illinois mailings have featured numerous materials targeting Governor J.B. Pritzker or promoting his Republican challenger, Darren Bailey. The fake newspapers don‘t appear on a regular schedule. Many „articles“ contain inaccurate information or push conservative talking points about issues such as COVID-19 and how schools approach sex education or gender identity. Pritzker has denounced the publications as “racist”; they have highlighted people of color alleged to have committed crimes.

Journalist and media critic Dan Froomkin, who runs the Press Watch website, told Bleeding Heartland, „The image of real news and fake news coming off literally the same presses—presses owned by a legitimate news organization—is horrifying.“

Froomkin added that the groups pretending to be news organizations „are inherently fraudulent. They do enormous damage to real news organizations both by misinforming people and by blurring the line between news and propaganda.“

Priyanjana Bengani of Columbia University‘s Tow Center for Digital Journalism recently published new research on a network of some 1,200 conservative sites purporting to provide local news. The sites have offered „a range of campaign services to conservative candidates“ before the 2022 elections. They are also running „stories that boost the positions of special-interest groups interspersed between thousands of algorithmically generated stories and republished press

releases.“

„While publishing news sites or newspapers to exert influence is not new,“ wrote Bengani in the Columbia Journalism Review on October 31, the network‘s tactics „create a challenge for independent local journalism and demonstrate how modern political campaigning makes it harder for readers to distinguish between political advertising and journalism.“

For Froomkin, „Fake news should be at the top of the list“ of things Gannett won‘t publish. „As news organizations, presumably including Gannett, fight to reduce the spread of disinformation on social-media platforms, the idea that they are letting groups like this use their own presses is incredibly hypocritical,“ he said.

In 2018, the Des Moines Register‘s editorial board joined more than 400 other newspapers in a coordinated effort to denounce then President Donald Trump‘s comments portraying accountability journalism as „fake news“ and reporters as „enemies of the people.“

Many Iowans received a fake newspaper purporting to be the „Iowa Catholic Tribune“ in October. The eight-page publication, not affiliated with any Catholic organization in Iowa, pushed negative storylines about Democratic candidates and positive messages about Republican ones, along with misleading information about abortion and LGBTQ materials in schools. Some of the content was nearly identical to the „Arizona Catholic Tribune,“ distributed around the same time.

The slogan „Real data. Real value. Real news“ appears on the fake Catholic newspaper‘s masthead, similar to what appears on the LGIS products in Illinois („Real data. Real news“).

Hunter told Bleeding Heartland the Des Moines Register‘s plant did not print the Iowa Catholic Tribune. Asked whether another Gannett facility printed that product, she referred the question to corporate communications.

UPDATE: A Chicago resident provided this photo of a newspaper that arrived in the mail November 5.

» drucken « zurück